Deviation within the prescribed movement could bring about boost in opportunity for microbial contamination. Content/personnel move is often modified, but the results of your modifications from a microbiological viewpoint needs to be assessed by liable managers and need to be approved and documented.

Resources that demand Distinctive disorders, for instance vacant capsule shells and hygroscopic powders, are stored in a region that's designed to maintain temperature and relative humidity requirements.

The pharmaceutical facilities that manufacture these products and solutions are designed and created To maximise effectiveness devoid of compromising product or service good quality or basic safety. So in which do you start while you are designing a non-sterile facility?

Checking of whole particulate rely in managed environments, even with using electronic instrumentation on a steady basis, will not offer information on the microbiological articles with the surroundings. The essential limitation of particulate counters is that they evaluate particles of 0.five µm or much larger. While airborne microorganisms are certainly not no cost-floating or single cells, they often affiliate with particles of ten to 20 µm.

These figures of particles are calculated For each class and for all particle dimensions through the system provided under-

Together with the swift advancement of biologic dependent medicines, additional chilly storage optimized for product dealing with is required for bulk drug substance, last drug product or service, biologic samples, whole lot samples, and clinical trial kits.

The GMP necessity will impression your cleanroom and facility design. You can find several methods to construct and design a cleanroom facility that could meet up with GMP requirements with the sterile production of medication. Here's a listing of issues you should know prior to elaborating on your design.

When dependent on the size and scope on the project, on average the whole guide time from initiation to final build and set up is in between sixteen and twenty weeks.

Microbial checking is usually evolving, with speedy detection approaches changing regular development-centered procedures. Technologies which include ATP bioluminescence and PCR-primarily based devices can provide ends in hrs instead of times, allowing for speedier corrective actions when contamination is detected.

When deciding on a centrifugal sampler, the impact on the sampler around the linearity from the airflow within the controlled zone where by it is actually put for sampling must be taken into account. Whatever the form of sampler used, using a remote probe necessitates determining that the extra tubing does not have an adverse effect on the viable airborne depend.

The managed setting is monitored by an acceptable environmental checking program. To guarantee that negligible bioburden is reached, additional information on the analysis of your microbiological status with the controlled environment could here be attained by the use of

Will need enable determining the best program? Don’t see That which you are trying to find? Seek advice from with FARRAR for any custom made solution to improve your procedure and make improvements to productiveness.

Isolator techniques need fairly rare microbiological monitoring. Continual complete particulate checking can provide assurance which the air filtration technique within the isolator is working adequately. The approaches for quantitative microbiological air sampling described During this chapter may well not have sufficient sensitivity to check the atmosphere inside of an isolator.

Identification of isolates from essential locations click here and spots fast to those essential areas really should get precedence above identification of microorganisms from noncritical locations. Identification solutions really should be confirmed, and prepared-to-use kits need to be skilled for their meant objective (see

Jake Lloyd Then & Now!

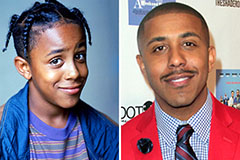

Jake Lloyd Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Matilda Ledger Then & Now!

Matilda Ledger Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now! Traci Lords Then & Now!

Traci Lords Then & Now!